Quality control in ceramic bathroom sanitary ware represents the cornerstone of delivering reliable, long-lasting products to the market.

Let me share my experience as a supplier to help you understand how manufacturers implement comprehensive quality control processes that ensure every sink and toilet meets international standards.

Key Quality Control Parameters For Ceramic Bathroom Sanitary Ware

Before diving into the detailed processes, it’s important to understand the fundamental parameters that define quality in ceramic bathroom sanitary ware. Manufacturers assess these key aspects throughout production:

| Quality Parameter | Testing Method | Acceptance Criteria | Impact On Product |

| Water Absorption Rate | 24-hour immersion test | ≤0.5% for vitreous china | Affects durability and hygiene |

| Surface Quality | Visual inspection + gloss meter | No visible defects at 60cm distance | Determines aesthetic appeal |

| Loading Strength | Static load test | 400kgs for toilets, 150kgs for wall-hung basins | Ensures safety and longevity |

| Glaze Crazing Resistance | Autoclave pressure test | No crazingafter 1-hour exposure | Prevents long-term deterioration |

| Flush Performance | Media discharge test | Complete evacuation in single flush | Ensures functional efficiency |

Surface Quality:

Ceramic products must show no visible defects when viewed from one meter under normal lighting conditions. This requirement ensures both aesthetic appeal and cleaning efficiency.

Moreover, surface quality testing goes beyond simple visual inspection. Using specialized equipment, quality teams measure gloss levels, surface smoothness.

Structural Integrity:

Toilets must withstand a minimum load capacity of 400kg, while wall-hung sinks have specific load requirements based on their design. This testing ensures long-term safety and durability in daily use.

Water Absorption:

For vitreous china, water absorption must not exceed 0.5%. This strict requirement helps ensure product longevity and maintains proper hygiene standards. Manufacturers verify this through standardized 24-hour immersion testing.

What’s The Key Quality Control Process In Ceramic Sanitary Ware Product Manufacturing?

As a supplier of high quality sanitary ware, I want to explain the comprehensive quality control process our manufacturing partner follow. Lt me walk you through how ceramic sanitary ware manufacturers maintain quality at each crucial stage.

Raw Material Selection and Inspection

The journey of quality bathroom sanitary ware begins with careful raw material selection. Manufacturing facilities focus intensively on this initial stage because the quality of raw materials directly determines the final product’s performance.

Quality inspectors at manufacturers carefully examine the clay body composition and glazing materials, checking not just its basic properties but also how it will perform throughout the production process, much like a chef inspecting ingredients before creating a complex dish.

Think of the clay body as the foundation of a building – just as a strong foundation ensures a stable structure, high-quality clay materials ensure durable fixtures.

Manufacturers test the clay’s plasticity, which determines how well it can be shaped into complex designs like toilets and sinks. They also analyze particle size distribution, which plays a crucial role in the final product’s strength and durability.

Pre-production Sample Approval

Before committing to mass production, manufacturers create multiple sample products for thorough evaluation. This critical stage serves as a dress rehearsal for full production, allowing quality teams to identify and address potential issues before they affect large-scale manufacturing.

They typically produce several test pieces under standard production conditions, testing not just the product design but also the production process itself.

During sample evaluation, quality inspectors examine both aesthetic and functional aspects. They verify dimensions using precise measuring equipment, assess surface quality under standardized lighting, and perform rigorous functional testing.

For toilets, this includes evaluating flush patterns and water efficiency. For sinks, they examine drainage characteristics and mounting stability. This comprehensive evaluation often reveals necessary adjustments that might not be apparent in technical drawings alone.

If you need to customize the products you want according to your requirements, usually at this stage the factory will make a few samples for you to confirm that there are no problems before formally starting mass production.

In-Process Quality Control

Quality control continues throughout the production process, with sanitary ware manufacturers maintaining specific checkpoints at each crucial stage. Let me walk you through these key inspection points and explain why each matters for the final product quality.

The Forming Stage

The forming stage requires careful monitoring of how the ceramic material takes shape. This stage is particularly critical because it establishes the basic structure of each plumbing fixture. Manufacturing quality teams check wall thickness consistency in sinks and toilets, they pay special attention to critical functional areas, such as flush channels in toilets or drainage paths in sinks, where precise shaping directly affects performance.

The Drying and Modification Process

The drying stage might seem straightforward, but it requires careful control of environmental conditions. Much like drying delicate fabric, ceramic pieces must dry evenly to prevent warping or cracking. Manufacturers maintain strict control over temperature and humidity levels throughout this process.

Quality inspectors regularly check pieces for any signs of defects that might develop during drying, such as warping or early crack formation. They understand that proper drying directly influences not just the immediate quality but also the long-term durability of the final product.

At the same time, after drying, there will be a professional worker to conduct a second inspection and modification of the ceramic body to ensure that the surface is flat and smooth enough. For factories with good quality control and general factories, some differences can be seen or felt on the surface of the products.

Glazing Quality Control

The glazing process requires an artist’s attention to detail combined with scientific precision.

Quality inspectors check for even coverage, proper thickness, and surface consistency. They look specifically for common defects like pinholes (tiny holes in the glaze), crawling (where glaze pulls away from certain areas), or blistering (bubble-like imperfections in the surface).

Think of glaze as both the protective skin and the aesthetic finish of the product – it must be both beautiful and functional.

The Critical Firing Stage

Firing represents a crucial transformation point where clay becomes ceramic. During this stage, sanitary ware manufacturers monitor temperature conditions throughout the kiln with the precision of a master baker.

The firing process must follow exact temperature curves – too hot and pieces may warp, too cool and they won’t achieve proper strength.

Quality inspectors look for signs of proper vitrification, the process that gives ceramic its characteristic strength and durability. This stage transforms a shaped piece of clay into a lasting fixture that can withstand years of daily use.

Final Product Inspection and Testing

The final inspection stage represents the ultimate quality gateway before sanitary ware products reach customers, the quality teams will conduct comprehensive evaluations before products leave the warehouse, incorporating detailed functional testing and precise measurements.

Of course, the strictness of the testing standards and procedures depends on the quality control of different manufactures.

If you are working with a trading company, they will usually have their own testing items or random inspections after the factory completes these processes or in combination with customer requirements.

Physical Property Testing

The sanitary ware manufacturers conduct several critical physical tests to verify product integrity. Water absorption testing, for example, reveals how well the ceramic body has vitrified during firing. In this test, products are weighed, submerged in water for 24 hours, and then weighed again.

The difference in weight, expressed as a percentage, must not exceed 0.5% for vitreous china. This seemingly simple test actually tells us a great deal about the product’s durability and hygiene properties – lower absorption rates mean better resistance to staining and bacterial growth.

Load-bearing capacity testing ensures fixtures can safely handle expected usage weights. Toilets undergo static load testing with weights of at least 400kg – imagine stacking four average adults’ weight onto a toilet seat.

Wall-hung sinks face similar challenges, with testing designed to simulate years of daily use and occasional excessive loads. These tests don’t just verify current strength; they help predict long-term durability under normal usage conditions.

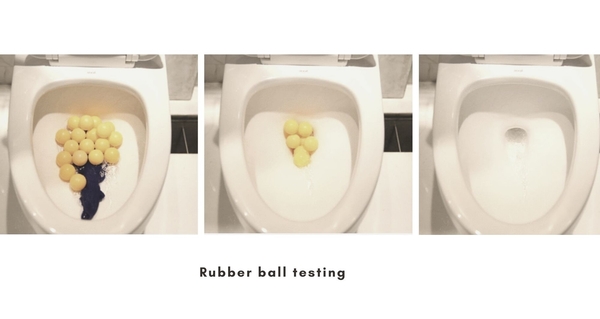

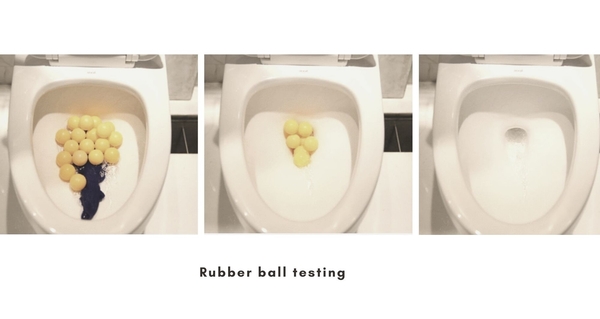

Functional Performance Evaluation

For toilets, manufacturers conduct thorough flush performance testing. This includes evaluating several key aspects: flush volume efficiency, bowl cleaning effectiveness, and trap way functionality. This can verify trap ways are properly formed and the water consumption meets efficiency standards.

Modern toilets must achieve these functions while meeting strict water conservation standards, making this testing particularly crucial.

While sink testing focuses on drainage efficiency, overflow functionality and mounting strength. If for wall-hung sinks, additional testing ensure secure mounting and verifies that the fixture remains stable under various load conditions.

Glazing and Surface Quality Assessment

Surface quality testing combines both technical measurement and practical evaluation. Under standardized lighting conditions, inspectors examine surfaces for any imperfections that might affect either appearance or functionality. They use gloss meters to measure surface reflectivity, ensuring consistency across the entire surface. Think of this like examining a painted wall – the finish should appear smooth and uniform from any angle.

Packaging and Loading Quality Control

Even the best-manufactured products require proper protection during transit. Normally the sanitary ware manufacturers will follow strict protocols for packaging, using industry-standard materials and methods that protect against typical shipping stresses.

Most factories will verify that products are properly cushioned and secured, with special attention to vulnerable areas like edges, and protruding features.

And if you are first time to work with a new supplier, better to make sure whether their cartons and loading methods are fit your requirement.

When we were working with factories, even if they had export experience, they only shipped full containers and had never tried bulk shipment. So when we proposed to packing with pallets, they had no idea what to pay attention to, such as the size of the pallet, the requirements for protect corners, how to use the packaging tape, whether need to use wrapping film, how much the total height of the pallet could not exceed, etc. They needed our instructions one by one to meet our basic requirements.

During container loading, the loading person with rich experienced will follow specific stacking patterns that distribute weight evenly and prevent pressure points. This attention to shipping quality ensures sanitary ware products arrive in the same pristine condition as the left the factory warehouse.

What’s The Global Standards and Quality Certifications For Sanitary Ware Industry?

The world of quality certifications provides a framework that ensures sanitary-ware products meet specific regional and international requirements. Each certification focuses on particular aspects of quality and safety, creating a comprehensive system of quality assurance.

Understanding certifications helps explain the comprehensive nature of quality control in our industry. Now let me explain some key certifications in sanitary ware industry and their significance.

ISO 9001

ISO9001 represents the foundation of quality management systems. This certification evaluates not just the products but the entire manufacturing process. It requires documented procedures, regular audits, and evidence of continuous improvement. Think of ISO 9001 as a roadmap for quality – it shows manufacturers how to consistently produce high-quality products.

CE Certification

CE Marking, essential for European markets, focuses heavily on safety and environmental protection. Products must demonstrate compliance with strict standards for mechanical strength, cleanability, and water conservation. This certification involves extensive testing and detailed documentation of results.

UPC/ CUPC Certification

UPC/ CUPC Certification stands as a critical requirement for North American markets. This certification involves rigorous testing that goes beyond basic functionality. Products must pass stringent tests for structural integrity, water consumption efficiency, and long-term durability. The testing includes advanced evaluations such as checking the effectiveness of trap ways in preventing sewer gas escape and verifying flush performance under various water pressure conditions.

WaterSense

WaterSense Certification, developed by the U.S. Environmental Protection Agency, recognizes products that exceed basic water efficiency standards. This certification requires products to use at least 20% less water than standard fixtures while maintaining equal or superior performance. Manufacturers must verify their products through third-party testing facilities, ensuring credibility in efficiency claims.

Watermark Certification

Certification, mandatory for the Australian and New Zealand market, places particular emphasis on water conservation without compromising performance. Products undergo extensive testing to verify they meet strict water efficiency standards while maintaining effective functionality. This certification considers Australia’s unique environmental challenges, making water conservation a primary focus alongside product quality and safety.

WELS

WELS (Water Efficiency Labelling and Standard) Certification provides consumers with detailed information about water consumption characteristics. Products receive ratings based on their water efficiency, helping consumers make informed decisions.

The star rating means the the water efficiency of the products. The more stars, the more water efficient the product is. And the number on the label means the rate of water consumption. Different kinds of products, the water consumption is different. Dishwashers, faucets and showers are tested Litres per-minute basis, while toilets and urinals are tested Litres per average flush and full flush basis.

NOM Certification

NOM Certification ensures products meet Mexican national standards for safety and performance. This comprehensive certification examines various aspects, from basic safety requirements to specific performance criteria adapted to regional needs. Products must demonstrate compliance through testing at approved laboratories, with regular audits to maintain certification.

SABER Certification

Saber Certification addresses the unique requirements of Saudi Arabia’s markets. This certification considers regional factors such as safety, quality standards, environmental conditions, and specific usage patterns. Products must demonstrate durability under challenging conditions while meeting strict quality and safety standards.

Common Defects in Ceramic Bathroom Sanitary Ware

Understanding potential defects helps explain the rigorous nature of sanitary ware quality control processes. Surface defects, while immediately visible, often indicate deeper quality issues. For instance, pinholes in glazing might seem purely cosmetic, but they can signal problems with glaze composition or firing conditions that could affect long-term durability.

Structural defects, while less common thanks to modern quality control, it require particular attention during production. Warping, for example, might develop during drying if environmental conditions aren’t precisely controlled. Cracks can appear during firing if temperature changes occur too rapidly. Manufacturers prevent these issues through careful monitoring and control of production conditions.

How effective quality control benefits for Bathroom Product Distributors?

Quality control directly impacts distributors’ business in several significant ways:

Reduced claims and returns:

When your sanitary-ware suppliers maintain strict quality standards, distributors experience notably fewer warranty claims and returns. This translates to lower operational costs and higher customer satisfaction.

Enhanced market reputation:

Consistently provide high-quality products help distributors build strong market reputations. Customers remember reliability, and this leads to repeat business and referrals.

Competitive advantage:

Quality-certified products often command premium market positions. This allows distributors to compete effectively on value rather than just price.

Simplified inventory management:

Reliable quality reduces the need for extensive safety stock, as replacements for defective products become rare rather than routine.

Practical Quality Verification Guidelines

Understanding how to verify product quality becomes essential for anyone involved in the bathroom sanitary ware supply chain. While manufacturers handle detailed testing, distributors and buyers should know key quality effectively in practical situations.

Visual assessment serves as the first line of quality verification. When examining ceramic sanitary ware, proper lighting proves crucial. Natural daylight or bright, even artificial lighting helps reveal surface variations that might indicate quality issues. Examine products from various angles, as certain defects become visible only from specific viewpoints. Pay particular attention to curved surfaces and joints, where manufacturing challenges often manifest as visible imperfections.

Functional verification requires a systematic approach to testing basic operations. For toilets, observe the water flow pattern during flushing. The water should distribute evenly around the bowl, creating an efficient cleaning action. Check that the flush mechanism operates smoothly and consistently.

For sinks, verify that water drains promptly and completely, without pooling in any areas. Test overflow mechanisms to ensure they activate at appropriate water levels and provide adequate drainage.

Documentation review plays a crucial role in quality verification. Each product should arrive with appropriate certification documentation. Verify that certificates remain current and match your specific market requirements. Remember that different regions may require different certifications, and maintaining proper documentation helps ensure compliance with local regulations.

Physical examination should include checking for structural soundness. Gently test mounted fixtures for stability. Examine joint areas where different components meet, ensuring proper alignment and secure connections. For wall-hung fixtures, verify mounting points show no signs of stress or improper installation.

Conclusion

Quality control in ceramic sanitary ware manufacturing represents a complex yet essential process that ensures product excellent.

While manufacturers handle the technical aspects of quality control, understanding these processes helps everyone in the supply chain appreciate the value of comprehensive quality management.

As markets continue evolving and environmental standards become increasingly stringent, maintaining high-quality standards grows ever more crucial. The future of plumbing fixtures manufacturing will likely see even more emphasis on water conservation and sustainable production methods, while maintaining the fundamental quality requirements that ensure product durability and customer satisfaction.

For distributors and suppliers, staying informed about quality control processes provides a competitive advantage in the market. This knowledge enables better product selection, more effective customer communication, and stronger partnerships with manufacturers.

The bathroom sanitary ware industry continues to advance, with new technologies and methods emerging regularly. However, the fundamental principles of quality control remain constant: attention to detail, systematic testing, and a commitment to meeting or exceeding international standards.

FAQ:

Question 1: What are the main quality certifications required for international markets?

Answer: Key certifications include ISO 9001, CE marking for Europe CUPC for North American, and Watermark for Australia. Specific markets may have additional requirements.

Question 2: What are the most critical quality control tests for ceramic toilet?

Answer: Water leaking test, Maximum performance (MaP) test and cleaning test.

One Response