Hello there! I’m a ceramic and porcelain tile supplier based in Foshan China, and I’ve been helping businesses around the world find the perfect tiles for their projects for many years. Today, I want to share what I know about ceramic tiles and why many importers choose to source them from China.

Ceramic tiles have become incredibly popular across the globe, and for good reason! The global ceramic tile market is huge – worth over $250 billion and growing every year. And did you know that China produces more than half of all ceramic tiles worldwide? That’s right – we’re the largest producer and exporter of ceramic tiles on the planet.

In this guide, I’ll walk you through everything you need to know about ceramic tiles, from what they’re made of to why importing from China might be the right choice for your business. Whether you’re just starting out as an importer or looking to expand your current product range, this information will help you make smart decisions.

What Are Ceramic Tiles? Understanding the Basics

What exactly is a ceramic tile?

Ceramic tiles are thin slabs made from clay and other natural materials that are shaped, dried, and then fired at high temperatures in a kiln. This firing process makes the tiles hard and durable, turning the soft clay into a solid material that can last for decades.

The word “ceramic” comes from the Greek word “keramos,” which means “pottery” or “potter’s clay.” People have been making ceramic products for thousands of years, but modern manufacturing has taken ceramic tiles to new levels of quality and variety. In nowaday, ceramic tile we usually refer to a ceramic tile in the broad sense, which includes porcelain tiles and ceramic tiles in the narrow sense (tiles with a water absorption more than 0.5%)

How are ceramic tiles made?

The manufacturing process for ceramic tiles is fascinating! Here’s a simple breakdown of how we turn clay into beautiful tiles:

- Clay preparation: We mix different types of clay with water and other materials to create the right consistency.

- Forming: The clay mixture is pressed into shape using large hydraulic presses that apply tons of pressure.

- Drying: The shaped tiles need to dry completely to remove moisture before firing.

- Glazing (for glazed tiles): A layer of liquid glass material is applied to the surface, which gives the tile color, pattern, and protection.

- Firing: The tiles go through a kiln at temperatures between 1,600°F and 2,200°F (800°C to 1,300°C).

- Quality inspection: Every tile is checked for defects before packaging.

The entire process takes careful control to ensure the tiles have the right strength, size, and appearance.

What are the main characteristics of ceramic tiles?

Ceramic tiles have several key features that make them popular for floors and walls:

- Durability: They can last for decades when properly installed

- Water resistance: Glazed ceramic tiles resist water, making them great for bathrooms and kitchens

- Easy maintenance: Simple to clean with just water and mild soap

- Design variety: Available in countless colors, patterns, and sizes

- Affordability: Generally less expensive than many other flooring options

- Hygiene: Don’t harbor bacteria, allergens, or odors

- Fire resistance: Won’t burn or release toxic fumes

These qualities have made ceramic tiles a favorite choice in homes and businesses around the world.

What Are the Different Types of Ceramic Tiles?

What types of ceramic tiles are available for walls?

Wall ceramic tiles are designed specifically for vertical surfaces where foot traffic isn’t a concern. They have these special characteristics:

- Lighter weight: Thinner profile (usually 6-8mm thick) to reduce weight on walls

- Decorative focus: More emphasis on appearance than durability

- Size variety: From tiny mosaics to large format wall tiles

- Glossier options: Shiny finishes that would be too slippery for floors

- Design variety: Textured surfaces, 3D effects, and decorative patterns

Wall tiles often come in subway formats (rectangular shapes), square formats, or decorative shapes like hexagons or arabesques. They’re perfect for kitchen backsplashes, bathroom walls, shower surrounds, and accent walls.

What types of ceramic tiles work best for floors?

Floor ceramic tiles need to withstand foot traffic, so they have different properties:

- Thicker body: Usually 8-12mm thick for better durability

- Higher strength: Designed to withstand weight and impact

- Slip resistance: Surface textures to prevent slipping, especially in wet areas

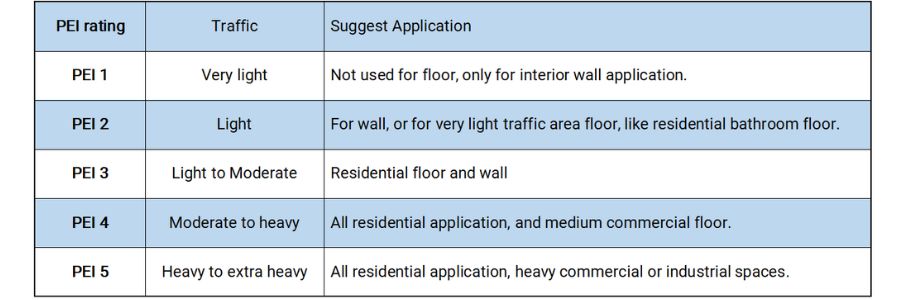

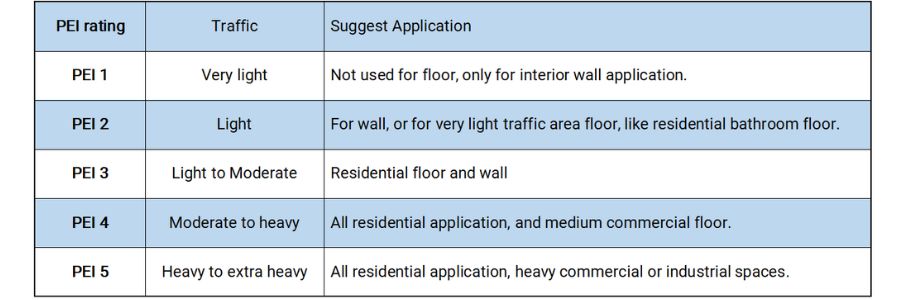

- PEI rating: A scale from 1-5 that tells you how much traffic the tile can handle

- Stain resistance: Better resistance to spills and dirt

For residential floors, look for ceramic tiles with a PEI rating of at least 3. For commercial spaces, you’ll want a rating of 4 or 5.

What are specialty ceramic tiles used for?

Beyond standard wall and floor tiles, we also make specialty ceramic tiles:

- Mosaic tiles: Tiny tiles (usually 2×2 inches or smaller) mounted on mesh sheets

- Decorative trim pieces: Special shapes like bullnose edges, chair rails, or corners

- Hand-painted tiles: Artisanal pieces with unique designs

- Textured tiles: With raised patterns for visual and tactile interest

- Swimming pool tiles: Specially designed for underwater use

These specialty tiles add unique touches to your projects and solve specific design challenges.

What Are the Technical Properties of Ceramic Tiles?

How do water absorption ratings work?

Water absorption is one of the most important technical properties of ceramic tiles. It tells you how porous the tile is, which affects where you can use it.

| Absorption Class | Water Absorption Rate | Best Uses |

| Non-vitreous | More than 6% | Indoor walls only |

| Semi-vitreous | 3% to 6% | Indoor walls and low-traffic floors |

| Vitreous | 0.5% to 3% | Most indoor applications |

| Impervious | Less than 0.5% | Outdoors, wet areas (technically considered porcelain) |

The lower the water absorption rate, the more durable and frost-resistant the tile will be.

What do PEI ratings mean for ceramic tile durability?

The Porcelain Enamel Institute (PEI) rating system helps you understand how much foot traffic a tile can handle:

- PEI Class 1: Wall use only, no foot traffic

- PEI Class 2: Light traffic areas (like bathrooms)

- PEI Class 3: Normal residential traffic

- PEI Class 4: Medium to heavy traffic (residential and light commercial)

- PEI Class 5: Heavy traffic (commercial spaces)

When choosing floor tiles, always check the PEI rating to make sure it’s appropriate for where you plan to use it.

What surface finishes are available for ceramic tiles?

The surface finish affects both how the tile looks and how it performs:

- Glazed: Has a protective layer of liquid glass that provides color and pattern

- Unglazed: The natural clay color shows through, giving a more rustic look

- Matte: Non-reflective finish that hides dirt and scratches better

- Glossy: Highly reflective and shiny

- Textured: Has a raised surface pattern for better slip resistance

- Polished: Smooth, reflective surface achieved through polishing

Glossy finishes look beautiful but can be slippery when wet. Textured finishes provide better grip but may be harder to clean.

What sizes do ceramic tiles come in?

Ceramic tiles come in a huge range of sizes:

- Mosaic: 2×2 inches or smaller

- Small format: 4×4, 6×6, 3 x 6 inches

- Standard: 8×8, 12×12, 12 x 24 inches

- Large format: 24×24 inches or bigger

- Plank: 6×24, 6×36, 8×48 inches (wood-look tiles)

The size you choose affects not just the look but also the installation requirements. Larger tiles mean fewer grout lines but require a more perfectly level surface.

Ceramic vs. Porcelain Tiles: What’s the Difference?

When shopping for tiles, you’ll often hear about both ceramic and porcelain options. While they’re similar in many ways, there are some key differences worth knowing about.

Ceramic and porcelain tiles are actually cousins – porcelain is technically a type of ceramic tile that’s made with more refined materials and fired at higher temperatures. This creates some important differences in how they perform.

Here’s a quick comparison of the main differences:

| Feature | Ceramic Tile | Porcelain Tile |

| Water Absorption | Usually 0.5-16% | Less than 0.5% |

| Durability | Middle to good | Excellent |

| Weight | Lighter | Heavier |

| Cutting Ease | Easier to cut | Harder to cut |

| Cost | More affordable | Generally more expensive |

| Best Uses | Indoor walls or floors | High-traffic areas, outdoors |

For a deeper dive into these differences, check out our detailed comparison post: Ceramic vs. Porcelain Tile

Remember that both ceramic and porcelain tiles can be excellent choices – it really depends on your specific needs and budget!

Why Should You Import Ceramic Tiles from China?

What makes Chinese ceramic tiles stand out in the global market?

As someone who’s been in the Chinese tile industry for years, I can tell you that China has become a ceramic tile powerhouse for several good reasons:

- Massive production capacity: China produces more ceramic tiles than any other country, which means more options and better availability.

- Excellent value: Chinese factories offer competitive pricing without sacrificing quality, giving you more bang for your buck.

- Advanced technology: Many Chinese factories have invested in state-of-the-art equipment from Italy and Spain, combining traditional expertise with modern technology.

- Design versatility: Chinese manufacturers can produce virtually any style, from classic to cutting-edge contemporary designs.

- Customization options: Many factories welcome custom orders with your specific designs, sizes, or technical requirements.

The combination of these factors has made China the go-to source for ceramic tiles worldwide.

How affordable are Chinese ceramic tiles compared to other sources?

One of the biggest reasons importers choose Chinese ceramic tiles is the cost advantage. Here’s a simple comparison:

- Chinese ceramic tiles: $3-$15 per square meter

- European ceramic tiles: $10-$40 per square meter

- Domestic production in many countries: $10-$25 per square meter

This price difference doesn’t necessarily mean lower quality. Chinese manufacturers have become experts at creating beautiful, durable tiles at prices that make sense for importers and distributors.

The cost savings come from:

- Efficient manufacturing processes

- Lower labor costs

- Economies of scale

- Abundant raw material resources

- Competitive factory ecosystem

These savings can significantly increase your profit margins or help you offer more competitive prices to your customers.

Have Chinese ceramic tiles improved in quality?

Absolutely! The quality of Chinese ceramic tiles has improved dramatically over the past decade. Many of our factories now:

- Hold international certifications like ISO 9001

- Meet or exceed international standards for ceramic tiles

- Use advanced quality control systems

- Employ skilled engineers and designers

- Invest in the latest manufacturing technology

The old stereotype of “cheap Chinese products” simply doesn’t apply to today’s ceramic tile industry. While there are still factories producing budget tiles, many Chinese manufacturers now create products that rival Italian and Spanish tiles in quality and design.

How to Navigate the Chinese Ceramic Tile Market

The Chinese ceramic tile industry is vast, with thousands of factories across the country. To give you a sense of what’s available without overwhelming you, here’s a brief overview:

Foshan city in Guangdong province is considered the ceramic capital of China, producing about 70% of all Chinese ceramic tiles. Other important ceramic production regions include:

- Qingyuan, Dongguan, Zhaoqing, Jiangmen in Guandong province

- Zibo and Linyi in Shandong province

- Wuzhou and Beiliu in Guangxi province

- Fuzhou and Quanzhou in Fujian province

Each region specializes in certain types of tiles, with different price points and quality levels.

For a more comprehensive guide to navigating the Chinese ceramic tile market, including how to choose suppliers and avoid common pitfalls, please check out our detailed China Tile Purchase Guides.

What Factors Affect the Cost of Ceramic Tiles?

Why do prices vary so much between different ceramic tiles?

Not all ceramic tiles are created equal! Several key factors influence pricing:

- Quality of raw materials: Purer clay and better-quality ingredients cost more but produce better tiles.

- Manufacturing technology: Advanced equipment produces more consistent tiles but costs more to operate.

- Design complexity: Intricate patterns, special glazes, or textured surfaces require additional processing steps.

- Size and thickness: Larger and thicker tiles use more material and are harder to produce without defects.

- Quality control standards: Stricter quality standards mean more tiles get rejected, increasing the cost of the approved tiles.

- Volume of production: Larger orders generally mean lower per-unit prices.

When comparing quotes from different suppliers, remember that these factors can explain price differences, and the cheapest option isn’t always the best value.

What are the hidden costs of importing ceramic tiles?

Beyond the base price of the tiles themselves, you should budget for these additional costs:

- Shipping: Ocean freight for heavy ceramic tiles can add $1-$3 per square meter

- Customs duties: Typically 0-15% depending on your country’s trade agreements with China

- Port fees and inland transportation: Getting tiles from the port to your warehouse

- Inspection costs: Third-party quality checks (highly recommended)

- Breakage allowance: Even with good packaging, expect some breakage (usually 1-3%)

- Warehouse storage: Tiles take up significant space

- Sample costs: Samples and courier fees during the selection process

A good rule of thumb is to expect the total landed cost to be 15-30% higher than the factory price.

What Are the Current Market Trends in Ceramic Tiles?

What designs and styles are popular right now?

The ceramic tile industry is always evolving, with new trends emerging each year. Some of the hottest trends I’m seeing right now include:

- Wood-look ceramic tiles: These mimic the appearance of hardwood but offer better durability and water resistance.

- Large format tiles: Bigger tiles (24×24 inches and larger) create a seamless look with fewer grout lines.

- Subway tiles with a twist: Classic subway tiles but with textured surfaces, unique glazes, or installed in interesting patterns.

- Geometric patterns: Hexagons, diamonds, and other shapes are replacing traditional square tiles.

- 3D textured tiles: Tiles with raised surfaces that create visual interest and tactile appeal.

- Earth tones: Warm beiges, terracottas, and subtle greens are making a comeback.

- Terrazzo-look tiles: The speckled appearance of terrazzo in an easier-to-maintain ceramic format.

These trends influence what factories produce and what’s available for import.

How is technology changing ceramic tile manufacturing?

Technology is revolutionizing ceramic tile production in exciting ways:

- Digital printing: Allows for incredibly realistic stone, wood, and fabric looks with unlimited design possibilities.

- Large format production: New presses can create huge tiles up to 48×48 inches.

- Thinner tiles: Advanced technology allows for durable tiles as thin as 3-4mm, saving material and shipping costs.

- Improved durability: New glazing techniques are creating more scratch-resistant and stain-resistant surfaces.

- Environmental improvements: More efficient kilns reduce energy use and emissions.

These technological advances mean today’s ceramic tiles offer better performance and more design options than ever before.

FAQ

How long do ceramic tiles last?

With proper installation and maintenance, ceramic tiles can last 10-20 years or even longer. In fact, in some ancient buildings, ceramic tiles have remained intact for centuries!

The lifespan depends on:

- Quality of the tile

- Proper installation

- Foot traffic levels

- Maintenance habits

Glazed ceramic tiles may show some wear on the surface over time, especially in high-traffic areas, but they generally don’t need replacement until you’re ready for a style change.

Are ceramic tiles good for bathrooms?

Yes! Ceramic tiles are an excellent choice for bathrooms because:

- They resist water and humidity when properly installed

- They’re easy to clean and don’t harbor bacteria

- They come in endless design options

- They’re more affordable than many alternatives

For bathroom floors, make sure to choose tiles with adequate slip resistance. For shower walls, properly installed ceramic tile with quality grout and sealer will provide years of trouble-free service.

How do I clean and maintain ceramic tiles?

Ceramic tiles are one of the easiest flooring options to maintain:

For regular cleaning:

- Sweep or vacuum to remove loose dirt

- Mop with warm water and a mild detergent

- Rinse with clean water if needed

- Dry with a clean towel to prevent water spots

For deeper cleaning:

- Use an oxygen-based cleaner or specialized tile cleaner

- Scrub grout lines with a soft brush

- Rinse thoroughly

Avoid:

- Harsh abrasives that can scratch the glaze

- Acidic cleaners on marble-look tiles

- Oil-based detergents that can leave a film

With minimal care, ceramic tiles will stay looking great for years.

How do I choose the right ceramic tile for my project?

To select the perfect ceramic tile:

- Consider the location: Different areas need different properties (slip resistance for bathrooms, durability for high-traffic areas).

- Check the PEI rating: Make sure it’s appropriate for your intended use.

- Think about maintenance: Lighter colors and busier patterns hide dirt better.

- Match your style: Choose tiles that complement your overall design scheme.

- Consider the size: Larger rooms generally look better with larger tiles.

- Set a realistic budget: Remember to include installation costs.

Always order samples before making a final decision, and view them in the actual space where they’ll be installed.

Conclusion

After reading this guide, you should have a good understanding of what ceramic tiles are, why they might be right for your projects, and why importing from China can be a smart business decision.

As a supplier based in China, I’ve watched the ceramic tile industry here grow from basic production to world-class manufacturing. Today, Chinese ceramic tiles offer an unbeatable combination of quality, variety, and value.

Whether you’re looking for simple subway tiles for a residential project or specialized technical tiles for a commercial space, Chinese manufacturers can meet your needs at competitive prices.

If you’re considering importing ceramic tiles, I encourage you to:

- Research thoroughly and understand exactly what you need

- Work with reputable suppliers with proven track records

- Request samples before placing large orders

- Consider using inspection services for quality assurance

- Plan carefully for shipping and logistics

For more specific advice on importing ceramic tiles from China or to explore our product range, don’t hesitate to contact us. We’re here to help you navigate the world of ceramic tiles and find the perfect products for your business.